|

|

|

| HOME >>HH-3 A-60 Class Fireproof Deck |

|

| |

|

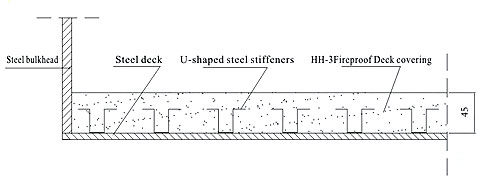

| 一.Structure Type: |

|

| 二.Technical Index: |

No. |

Item name |

Index |

Executive standard |

1 |

HH-3 Fireproof Deck Covering |

Initial setting time |

≥1h |

Q/HCF 1-2004 |

2 |

Final setting time |

≤12h |

3 |

Modulus of rapture |

≥4MPa |

4 |

Compressive strength |

≥20MPa |

5 |

Density |

≤1600kg/m3 |

6 |

Water absorption |

≤10% |

7 |

Oil absorption |

≤5% |

8 |

Heat conductivity |

≤1.2W/m.k |

9 |

Non-combustibility |

In accordance with IMO.FTPC Part 1/IMO.A 799(19) |

10 |

Deck

Structure |

Fire Rating |

A-60 |

11 |

Weight per square meter |

≤60 kg/m2/45mm |

|

| 三.Property: |

Characteristic: Fire rating is A-60 class and has very strong moisture-proof

Applicable for: Covering for A-60 class decks and damp cabins

Consume amount: 60 kg/m2

Packing: Dry material (A component): 30kg/pack

Storage: Cool and dry place, moisture-proof, the quality guarantee period is 6 months

Approval Certificate: ABS、BV、CCS、DNV、EC、GL 、KR、LR、NK |

| 四.Application Method: |

4.1 Preparation prior to application

4.1.1 The U-shaped steel stiffeners which the interval is 300mm shall be welded onto the steel decks, the other welding and fairing by hot working on the steel decks that may interfere with the application of covering are to be finished beforehand.

4.1.2 The oils, water, anticorrosive paints, impurities on steel plates are to be removed meanwhile the surface preparation is carried out according to the requirements of Grade P2 of CB3230 or Grade St2 of ISO8501-1.

4.2 Application Procedures

4.2.1 Stir the dry materials (A component) evenly near the construction site or in agitator, according to the ratio of covering and water which is about 6:1 on weight, and pour the covering onto the steel deck plate, rub the covering back and forth with a trowel to moisture the steel decks sufficiently, then striking off the covering with wooden ruler, and consolidating and leveling the covering surface with trowel.

4.2.2 After the covering application finished, it should be kept maintain for 1 to 2 days with spray a suitable amount of water or maintaining agent on its surface, and people may walk on it. After the covering completely hardened, the floors can be adhered.

4.2.3 In the whole application and maintenance period, the environmental temperature should be a range of 0~35℃, cool-down measure is to be taken if the temperature is higher than 35℃ or heat preservation measure is to be taken if the temperature is lower than 0℃. |

| 五.Attentions |

5.1 The dry material (A component) shall be kept in dry place, avoid rain showering or water dipping. If the cement is obviously caked, it shall not be used.

|

|

|

|

|